MF formwork panels for sophisticated exposed concrete project in Switzerland

Urban living is being realized in Lucerne, Switzerland - in an ensemble consisting of three buildings with 155 apartments and studios of different sizes plus communal and commercial areas. The architects opted for fair-faced concrete architecture; Westag formliners provided impressive fair-faced concrete surfaces.

Urban living can be beautiful - in modern but affordable apartments close to the city center with well thought-out floor plans and in the midst of a lively social environment. In Lucerne, Switzerland, this is being realized in an ensemble consisting of three buildings with 155 apartments and studios of different sizes plus communal and commercial areas. The architects opted for exposed concrete architecture; Westag-Schalhaut provided impressive exposed concrete surfaces.

In the Bernstrasse quarter, in the center of the city with more than 82,000 inhabitants, the Lucerne building and housing cooperatives abl and Matt are jointly building an ensemble with apartments, studios and commercial space with communal indoor and attractive outdoor areas. It will be built and operated sustainably in accordance with the target values of the 2000-watt society. The Basel-based architecture firm Luca Selva AG won the project competition. Schmid Bauunternehmung AG from Ebikon has been entrusted with the construction work. The project will be completed by early summer 2024.

Solid construction - self-supporting facades

The solid construction houses consist of walls made of sand-lime brick and concrete and floor slabs made of concrete. The façades are self-supporting and do not take on any static functions. The load transfer is ensured by the directly superimposed transverse walls, the staircase cores and - where necessary - by supports in the building envelope. The three compact building volumes, some of which are founded on bored piles, stand above a continuous parking garage and the basement levels. These take account of the striking topography and are therefore stepped and sloped several times.

The nine studios on the first floors of the upper Bernstrasse offer plenty of space for creative ideas. The 54 to 76 m² spaces are designed on two levels and are characterized by different room heights. Where the Bernstrasse Quarter with five full storeys and an attic storey is now being built, there were previously individual older buildings. The architects had to react to an existing easement during the planning phase. Luca Selva Architekten solved the challenge by inserting a neighborhood square into the critical section and only building further back.

Clever integration into the surrounding buildings

Despite its enormous dimensions, the bright and inviting architecture of the entire quarter does not make it look like a foreign body, but rather cleverly integrates it into the surrounding buildings. Michael Hörmann, consultant at formwork specialist Westag AG, supervised the construction project and advised the contractors on formwork technology: „The focus was on our Betoplan Top MF and the new Magnoplan Duo MF formwork panel, a further development and extension of the Westag MF concept and a suitable addition to Betoplan Top MF. In areas where only medium application rates are required, the Magnoplan Duo MF offers an economical solution and achieves an optimum surface finish and appearance of the concrete. With a coating of 550 g/m², it has the same technical values as Betoplan Top MF. In many tenders, this formlining is explicitly requested by the architects.“ As architect Lukas Schirmann emphasizes, Betoplan Top MF is a good choice for architects for exposed concrete formwork.

Betoplan Top MF mounted on girder formwork

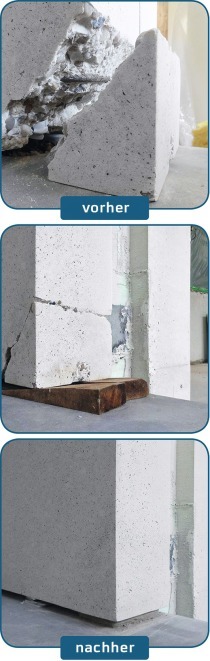

For the façade, Betoplan Top MF was designed and used on girder formwork. Schmid Bauunternehmung AG was responsible for planning and implementing the architect‘s specifications. Inlays and formwork were installed on site. The mock-up erected at the start of construction and the sample surfaces clearly illustrate the design considerations and attempts to achieve an optimum result with different concrete mixes and formwork panels.

Lukas Schirmann: „After critical examination of the exhibits by our office, the site management and the client, the advantage of melamine resin-coated formwork panels became clear. The expert installation of the building material also helped to deliver a convincing result. This was particularly true of the architecture: lattice and perforated façades with projecting polygonal bays as well as the soffits in white cement fair-faced concrete.“ 17,000 m³ of ready-mixed concrete is required, 2,500 m³ for the façade. The concrete was installed using crane buckets; formers and needles ensured good compaction of the building material. Precast concrete elements were used for the flights of stairs and the columns in the parking garage. The clean craftsmanship of the construction work, even with difficult components, was evident during the press tour: good compaction, even surfaces and uniform coloring. Only occasionally was cosmetic work required to achieve a better result.

Exposed concrete façades concreted in front of the floor ceilings

Martin Nussbaum: „The exposed concrete façades in front of the floor walls and ceilings were always concreted first, joints and binding holes were sealed or taped on the inside and binding holes were filled on the inside in accordance with the standard. The exposed concrete work, including the reinforcements, had to be fully protected against rust water after each work stage. The dimensions of the formwork had a standard width of 2.00 m and a height of 2.90 m.“

Superblanc white cement in accordance with the SN EN 197-1 standard was used for the defined concrete quality, and the concrete surfaces (class BOK 3) had to have a uniform color structure, a low proportion of air voids and no gravel pockets. The tender required sharp edges, very smooth surfaces, increased requirements for crack limitation, frost resistance and the surfaces to be deeply hydrophobic and graffiti protected.

Photovoltaics and green roof

The building is supplied with daylight via generous perforations in the façades. These generate a carefully proportioned „grid façade“ made of light-colored white cement concrete, which remains visible. The façade is insulated and clad from the inside. According to the architects, this results in a very low-maintenance but durable façade.

The triple-glazed windows in the apartments are made of wood and metal, while the public areas are made of aluminum. The fall protection of the windows, balconies and terraces is achieved by means of the exposed concrete façade and glass balustrades. High-quality external slats and the solid construction method with the provision of thermal storage mass are intended to provide excellent conditions for thermal insulation in summer.

The main roofs (roof areas above the attic storey) are planned with a photovoltaic system. The secondary roofs (roof areas above the fourth floor) are greened (extensive greening Lucerne mix) and in some cases designed as accessible attic terraces. Heat for heating and hot water is supplied all year round via the district heating connection, which is currently being extended to the Lucerne-Littau district. As much of the electricity used on the site as possible will be generated by photovoltaic systems on the main roofs. Each part of the building has its own building services rooms. By connecting the plant rooms to the stairwell cores, it is possible to distribute the cables vertically.

Michael Hörmann from Westag is certain: „Fans of pioneering exposed concrete buildings will find many other examples in Switzerland. For example, the FC Basel youth campus, also planned by Luca Selva Architekten, was given shape with the help of Westag Betoplan Top and Phenox 360 formliners.“